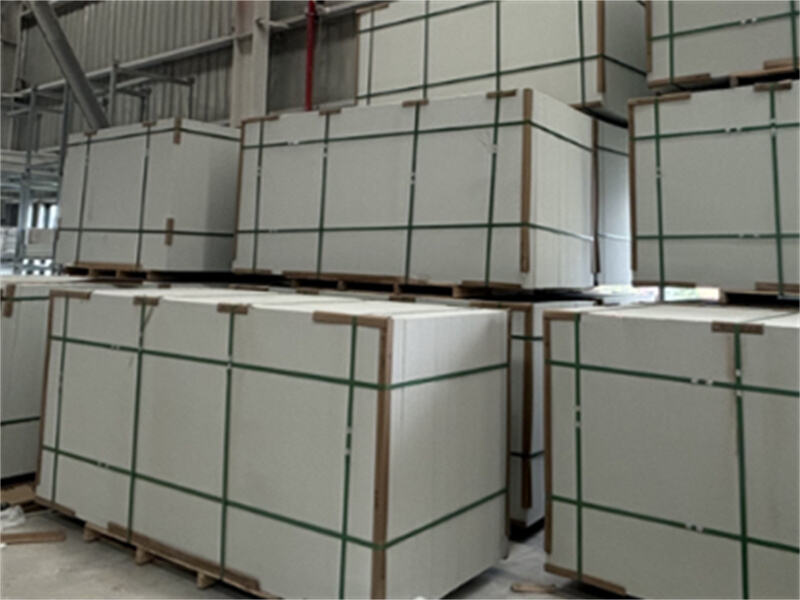

Recently, the "Glass Ceramic Path" team at Jiangxi University of Science and Technology has made breakthrough progress in the field of green building materials. They have successfully developed a new technology for co-preparing foam ceramics using waste glass and kaolin, providing an innovative solution to the problems of traditional foam ceramics, such as low compressive strength, susceptibility to water absorption and penetration, high energy consumption, and high production costs.

In response to the national call to establish a waste recycling system, the team spent four years visiting dozens of counties and conducting in-depth research in hundreds of villages, thereby constructing a new model for resource regeneration and transformation.

By virtue of the domestically pioneered "super-efficient foaming activation technology" and "firing parameter optimization technology", the team has successfully increased the utilization rate of waste glass to over 90%. Moreover, the compressive strength of the product has exceeded 13 megapascals, showing a significant improvement compared to traditional products, while production energy consumption has been greatly reduced.

At present, we team has published more than ten high-level papers, obtained several core technology patents, and passed authoritative institution testing and certification. The project is expected to achieve a profit of over 10 million within five years, create more than 2000 jobs, recycle hundreds of thousands of tons of waste glass, and contribute to the transformation of green buildings and rural revitalization.

Hot News

Hot News2025-11-14

2025-11-07

2025-10-28

2025-10-20